Thank you for the questions. Writing the blog takes me away from repairing bases shredded by the gravel-laced snow we are so thankful for.

Anyway- the question was this: "Should I use a colder or warmer wax on Salt treated snow?" Good question! The quick answer is Colder- about 2 ranges colder than the ambient conditions (generally) indicate- because the snow is colder and MUCH more abrasive. If those 37 f temps were telling you to apply HF10 wax (a very good wax in wet mush), the salt should have you changing to about HF7, The salt made the snow colder AND more abrasive to the bases.

To explain why this is true, here is a short refresher on Wax Properties.

ALL ski wax has 3 general properties/purposes. They are

- Base Protection

- Friction Reduction (or Glide) and

- Cleaning (and dirt rejection)

When you are choosing which wax to use, you must consider what your priorities are, and what functions you want the wax to perform.

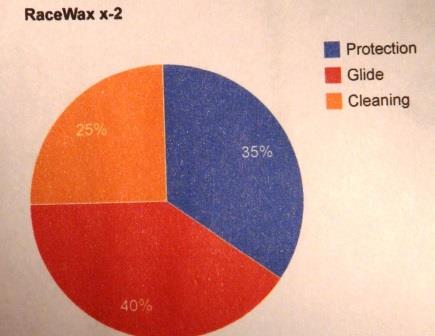

This chart is an example of what I am talking about.

NO wax can perform all functions at once perfectly, they each are a balance of available properties. Some properties are complimentary, some are opposing each other. And the application changes how the properties interact.

Properties that oppose (generally):

Glide and Protection:

Why? Because glide relies on softer wax components that "go away" as you ski- like fluro, silicone, etc. Protection relies of Harder wax components that are more durable

Properties that (can) be complimentary:

Cleaning and glide:

Why? Because dirt is slow, REALLY slow. Waxes that help keep skis cleaner also keep them faster.

Additives that "extend" the range and purpose of a wax:

Molybdenum, and Flurocarbons (fluro). Why? Because Moly is friction reducing, static reducing, AND it is (somewhat) of a hardener. Sounds ideal, right? Fluro is friction reducing and dirt-rejecting. It is possible to make a hard, yet pretty fast wax by loading it up with these 2 additives. One wax that does EXACTLY that is Swix Marathon.

Example 1:

- EXTREMELY cold day (-20f).

- Wax: SWIX CH4 with CH3 hardener.

- Properties:

- Protection: 70%

- Glide: 29%

- Cleaning: 1%

But on a VERY cold day, the abrasion protection provided by this extremely hard wax combo will actually ADD to glide by preventing the snow from cutting the base.

Eample 2:

30 f old snow, melting slightly in the sun.

- WAX Swix HF8BW

- Properties:

- Protection: 25 %

- Glide: 55 %

- Cleaning: 20 %

In this case, the HF (High Fluro) helps with glide AND dirt rejection.

The actual wax that I use most of the time on Salty course:

RaceWax X-2 (don't tell anyone- it's a secret).

As you can see in the chart above, it is a great blend of performance, cleaning, and protection.

Other suitable waxes include Swix HF7, HF7BW, and other similar equivalent waxes.

In my post that follows, you will get a glimpse into how I decide these things.

I'm outta here!!

-John